Yokogawa Distributed Control System (DCS) ensures reliability through redundant architecture and offers seamless integration. When installed along with Siemens PLC assemblies, they enable advanced diagnostics and real-time control, streamlining complex industrial processes.

Monitorable and high-availability hardware is a must for Distributed Control Systems, which form the basis of modern industries. Thus, it is important to opt for devices that offer seamless integration while building reliable industrial architecture.

Let’s take a look at how reliable infrastructure can be achieved in large-scale process automation by option for the Yokogawa Distributed Control System.

Why Reliability is Important in Large-Scale Process Automation

Large-scale industries often face the following challenges when it comes to process automation:

- Inefficient process flow

- Lack of scalability

- Presence of multiple standalone processes

- Incompatible and outdated legacy systems

For continuous operations and efficient workflow, it is important to resolve all of the above, establishing a reliable industrial infrastructure. Reliability and uptime are critical in industries such as oil and gas, chemical, power, automotive, and others.

This offers:

- Reduction in overhead and maintenance costs.

- Better productivity by reducing speed losses and minor stops.

- Improved output and product quality.

- Establishing safe, stable industrial processes.

- Cut back on downtime due to equipment failure.

To achieve this, industries opt for top-of-the-line process control systems such as the Yokogawa Distributed Control Systems and Siemens PLC assemblies. Both devices offer fault tolerance, system redundancy, system status monitoring, and predictive analytics.

Overview of Yokogawa Distributed Control System (DCS)

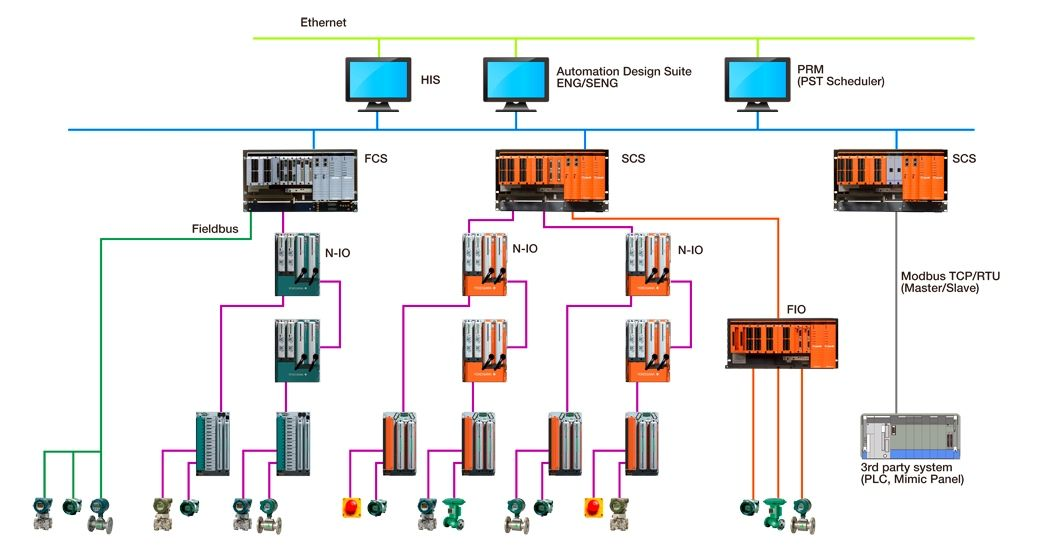

The Yokogawa Distributed Control System (DCS) is a centralized automation system that offers an overview and control of complex industrial processes in real time. The key components that are connected to the DCS system include I/O modules, HMIs, and field devices.

Key features of Yokogawa DCS include:

- High system availability through redundant systems.

- A fail-safe design that keeps operating even with component failures.

- Scalable, flexible architecture.

- Real-time data analytics for process optimization.

- Advanced process control and data management capabilities.

- Comprehensive suite of engineering functions and configuration.

- Smart operation tools to improve plant performance.

- Seamless integration with other systems.

- Certified cybersecurity features.

- Enterprise-wide interoperability for large and complex industrial processes.

Core Reliability Features of Yokogawa DCS

The core reliability features that make the Yokogawa Distributed Control Systems one of the best industrial systems are:

- Redundant controllers and communication networks for zero downtime.

- Fault-tolerant system design and Pair-and-Spare architecture that allows continuous operation even with system failure.

- Presence of real-time diagnostics and predictive maintenance tools.

- Fail-safe design offering 99.99999% availability.

- Isolated controllers to keep every process monitorable at all times.

- Robust, modular design that makes the system inherently scalable.

- Seamless failover and hot-swapping capabilities.

- Cybersecurity measures integrated into the control architecture.

- Complete system integration for unified operations.

- Intuitive HMI for quick and accurate decision-making.

A tabular representation of the features offered by the Yokogawa DCS systems is as follows:

| Reliability Feature | Description | Benefit |

| Redundant Controllers | Duplicate controllers run in parallel | Eliminates single-point failures |

| Network Redundancy | Dual communication pathways | Ensures continuous data flow |

| Real-time Diagnostics | Continuous system health monitoring | Prevents unexpected breakdowns |

| Hot Swapping | Replace components without shutdown | Minimizes downtime |

| Isolated Controllers | Controllers that are designed to run even in the case of system failures | Prevent processes from becoming unmonitorable |

Table 1: The list of features that make the Yokogawa Distributed Control Systems reliable.

Integration with Siemens PLC Assemblies

For efficient process automation, Yokogawa Distributed Control Systems can be integrated with Siemens PLC Assemblies. These are compatible devices, which, when installed together, offer:

- Efficient real-time monitoring

- Automation of repetitive tasks

- Efficient data acquisition and processing

- Enhanced process safety

- Improved diagnostic and troubleshooting capabilities

Yokogawa DCS and the Siemens PLC operate on a unified architecture offering hybrid control solutions. By using the system integration OPC station (SIOS), operators can monitor and operate integrated PLC units.

The benefits of combining DCS precision with PLC flexibility include:

- Enhanced adaptability

- Improvement in operational efficiency

- Better data management

- Increase in system reliability and scalability

- Greater process coordination

Comparing Yokogawa DCS and Siemens PLC for Large-Scale Automation

Some industries either opt to install only the Yokogawa DCS or the Siemens PLC Assemblies. Thus, to highlight differences in system architecture and typical use cases, the Yokogawa DCS and Siemens PLCs can be compared as follows:

| Aspect | Yokogawa Distributed Control System | Siemens PLC Assemblies |

| System Architecture | Distributed, redundant control system | Modular, centralized programmable logic controllers |

| Best Use Case | Complex process industries with large-scale automation | Discrete manufacturing, smaller processes, or integration in hybrid systems |

| Reliability Features | Built-in redundancy, hot-swap, diagnostics | High modularity, fast response time |

| Integration Capability | Strong integration with multiple PLC brands | Can be integrated with DCS systems |

Table 2: A brief comparison between Yokogawa Distributed Control System and Siemens PLC Assemblies.

Real-World Applications: Yokogawa DCS in Action

Opt for the Yokogawa Distributed Control System for large-scale operations and integrated plant control. For controlling individual machines or units, it is better to opt for Siemens PLC Assemblies.

Some applications where we can find the DCS in action are:

- Oil and Gas: Plant monitoring, quality control, and safety.

- Chemicals: Controlling production processes.

- Power Generation: Monitoring and control of process equipment and transmission lines.

- Pharmaceuticals: Process automation and quality control.

- Mining and Metallurgy: Monitoring, automation, and process safety.

- Wastewater Treatment: Data management and process monitoring.

- Food and Beverage: Automating and monitoring processes.

Wrapping Up

The Yokogawa Distributed Control System acts as the backbone of reliable automation in process industries with the benefits it offers. For further versatile and efficient automation, these DCS systems can be paired with the Siemens PLC assemblies.

Installing Reliable Automation Solutions

Looking for reliable automation solutions for your large-scale process plant? Discover how Yokogawa Distributed Control System, combined with Siemens PLC assemblies, can maximize uptime and efficiency for your industry.