Creating strong and accurate prototypes is key to making better products. That’s where machine casting solutions come in. These advanced methods help shape metal parts quickly and precisely. They save time, lower costs, and improve quality during the early design stages.

Whether you’re building car parts or tools, machine casting solutions give you the edge you need to succeed in today’s fast-moving world of manufacturing. Read on.

The Role of Machine Casting in Modern Manufacturing

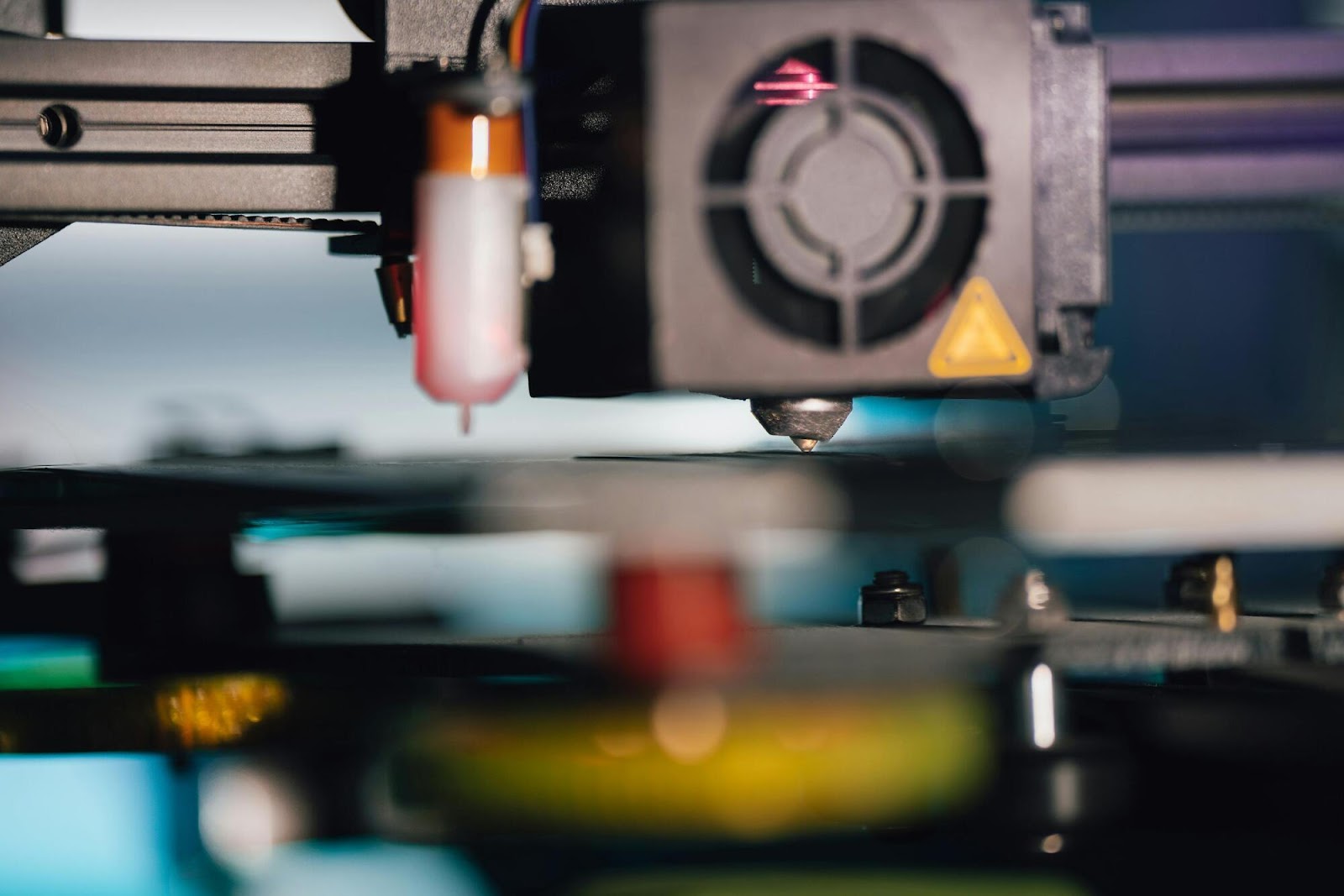

Machine casting is a method used to form metal parts with great detail. It uses molds to shape metals into specific designs. This method is ideal for early product testing and development.

Using machine casting helps reduce errors and speeds up the process. It also allows for better control over the final product. These benefits make it a top choice in many industries today.

Benefits of Using Casting for Prototypes

Casting gives you a fast and reliable way to make parts. It is great for testing new ideas before full production. The parts made are strong and closely match the final product.

With casting, you can test how a product looks and works early on. This helps catch problems before they become costly. That’s why casting is a smart step in prototype manufacturing.

How Precision Casting Technology Improves Accuracy

Precision casting technology helps make very detailed parts. This method uses advanced tools to create fine features in metal pieces. It is ideal when accuracy is a top priority.

These casting systems reduce the risk of mistakes in the design. They help produce parts that fit exactly as planned. This leads to smoother testing and faster changes if needed.

Speeding Up Development with Rapid Prototyping Methods

Speed matters in product development. That’s why many companies use rapid prototyping methods. These methods allow for quick changes and faster testing.

Casting fits well with rapid development needs. You can make parts quickly and test them in real use. This shortens the time it takes to get a product ready for market.

Creating a Working Prototype with High-Performance Casting Systems

To create a working prototype, you need parts that last. High-performance casting systems are designed to make durable parts fast. They handle complex designs with ease.

These systems also support different metals and shapes. That gives engineers more freedom to try new ideas. It’s a smart way to move from concept to real product.

Trusted Experts Can Help You Get Started

If you want to use machine casting for your next project, expert help is key. You can visit Griffin Industries to learn more. They offer professional casting services and guide you through the process.

Working with experts makes everything easier. They understand what works and what doesn’t. This can save you from costly mistakes and delays.

Machine Casting Solutions: A Smarter Way to Innovate

Machine casting solutions help teams build better prototypes. They offer speed, accuracy, and strong parts for testing. With these tools, mistakes are fewer and changes are faster. This means products can reach the market sooner.

From simple parts to complex designs, casting can handle it all. It also supports different metals and shapes. That makes it a smart choice for many industries. Machine casting solutions are a key step in turning ideas into real, working products.

Did you find this article helpful? Visit more of our blogs.